Facts to Consider Split Seal Rings

Split seal rings are a relatively new product that many industrial enterprises have adopted and enjoyed. But what information about these seal rings do you need to know? To find out more, you should read this article.

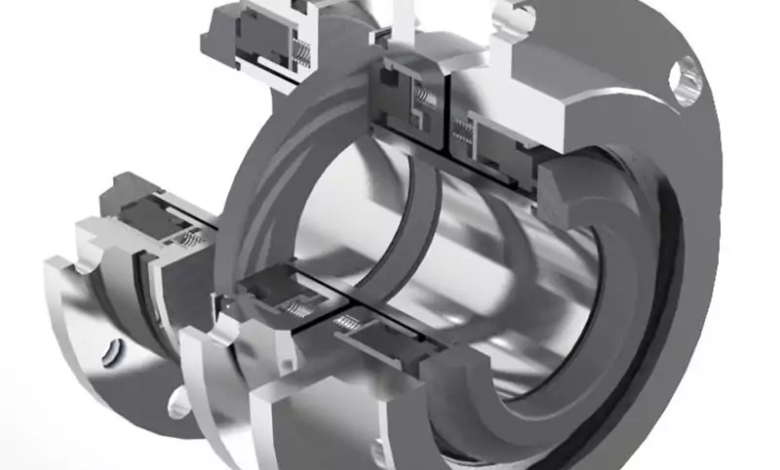

Split seal rings: what are they?

Split seal rings are frequently utilized in applications that demand a watertight seal. The seal is made by two halves of the ring together after they have been split in half. This kind of closure is frequently employed in locations where a conventional rubber gasket watertight seal is challenging or impossible. A split seal ring is composed of two distinct components hinged together. Thanks to this hinge, it is simpler to replace the seal ring when the two components can open and close separately.

What other applications may a split seal ring be used for?

Split seal rings are most frequently utilized as watertight seals between various machine components, such as between the motor’s internals and its exterior shell. Additionally, they are utilized in petroleum applications such as gas pipes. Split seal rings come in various styles and sizes to suit various requirements.

Why Junty?

You should know a few things about Junty when providing seals for your items. Junty is, first and foremost, a top supplier of split seal rings. These rings are necessary to keep things sealed and shielded from the environment. They are also frequently employed in the food and automotive industries, where they are essential for safeguarding ingredients and avoiding contamination.

Second, Junty provides a staggering selection of sizes and styles for various applications. This implies that you can locate a split seal ring that ideally meets your requirements. Finally, Junty is renowned for its excellent standards, guaranteeing the dependability and durability of all its goods. So, if you have any wants or questions, don’t hesitate to contact Junty.