Motronic Gasoline Direct Injection (GDI)

Introduction

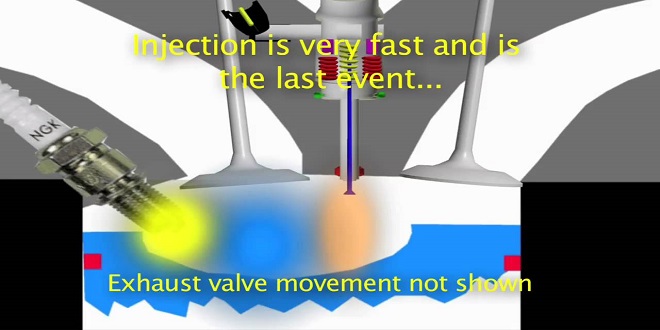

Bosch’s high-pressure injection system for gasoline engines is based on a pressure reservoir and a fuel rail, in which a high-pressure pump charges to a regulated pressure of up to 120 bar. The fuel can therefore be injected directly into the combustion chamber via electromagnetic injectors. This system achieves reduced emissions and improved fuel consumption.

The air mass drawn in can be adjusted through the electronically controlled throttle valve (gas-by wire) and is measured with the help of an air mass meter. For mixture control, a wide-band oxygen sensor is used in the exhaust. It is positioned before the catalytic converters. This sensor can measure a range between lambda 0.8 and infinity.

The electronic engine control unit regulates the operating modes of the engine with gasoline direct injection in three ways:

- Stratified charge operation – with lambda values greater than 1.

- Homogenous operation – at lambda 1.

- Rich homogenous operation – with lambda 0.8.

Compared to the traditional manifold injection system, the entire fuel amount must be injected in full-load operation in a quarter of the time. The available time is significantly shorter during stratified charge operation in part load. Especially at idle, injection times of less than 0.5 ms are required due to the lower fuel consumption.

This is only one-fifth of the available time for manifold injection. The fuel must be atomized very finely in order to create an optimal mixture in the brief moment between injection and ignition. The fuel droplets for direct injection are on average smaller than 20m.

may form. In order to prevent this, the DI-Motronic engine control converts to a homogenous cylinder charge at a pre-defined engine load. The system injects very early during the intake process in order to achieve a good air/fuel mixture at a value of lambda 1.

As is the case for conventional manifold injection systems, the amount of air drawn in at all operating modes is adjusted through the throttle valve according to the desired torque specified by the driver. The Motronic ECU calculates the amount of fuel to be injected from the drawn-in air mass and performs an additional correction via lambda control.

In this mode of operation, a torque increase of up to 5% is possible. Both the thermodynamic cooling effect of the fuel vaporizing directly in the combustion chamber and the higher compression of the engine with gasoline direct injection play a role in this

With stratified charge operation, the lambda value in the combustion chamber is between about 1.5 and 3. In the part-load range, gasoline direct injection achieves the greatest fuel savings with up to 40% at idle compared to conventional fuel injection.

Masstamilan is a popular website that offers Tamil songs for free downloads. It is a go-to platform for Tamil music lovers to find their favorite tracks easily.

Last word

In stratified charge operation, the nitrogen oxide (NOx) segments in the very lean exhaust cannot be reduced by a conventional, three-way catalytic converter. The NOx can be reduced by approximately 70% through exhaust returns before the catalytic converter. However, this is not enough to fulfill the ambitious emission limits of the future. Therefore, emissions containing NOx must undergo special treatment.