Combustion of ultra-lean mixture

n conventional MPI engines, there were limits to the mixture’s leanness due to large changes in combustion characteristics. However, the stratified mixture of the GDI enabled greatly decreasing the air-fuel ratio without leading to poorer combustion.

For example, during idling, when combustion is most inactive and unstable, the GDI engine maintains stable and fast combustion even with an extremely lean mixture of a 40 : 1 air-fuel ratio. shows a comparison between GDI and a conventional multipoint system.

Vehicle fuel consumption

Fuel consumption is considered under idling, cruising, and city driving conditions

Fuel consumption during idling

The GDI engine maintains stable combustion even at low idle speeds. Moreover, it offers greater flexibility in setting the idle speed. Compared with conventional engines, its fuel consumption during idling is 40% less, as represented.

Fuel consumption during cruising

At 40 km/h, the GDI engine uses 35% less fuel than a comparably sized conventional engine.

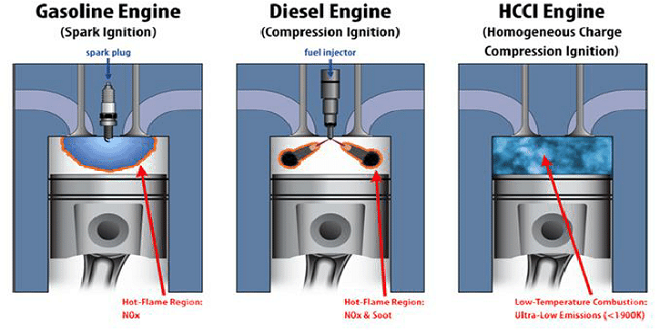

However, for the GDI engine, 97% NOx reduction is achieved by utilizing a high-rate EGR (Exhaust Gas Recirculation) such as 30%, which is allowed by the stable combustion unique to the GDI, as well as by the use of a newly developed lean-NOx catalyst. shows a graph of NO x emissions. 10.34 is a newly developed lean-NOx catalyst.

Fuel consumption in city driving

In Japanese 10.15 mode tests (representative of Japanese urban driving), the GDI engine used 35% less fuel than comparably sized conventional gasoline engines. Moreover, these results indicate that the GDI engine uses less fuel than even diesel engines.

Realization of superior output

Compared with conventional MPI engines of comparable size, the GDI engine provides approximately 10% greater output and torque at all speeds. In high-output mode, the GDI engine provides outstanding acceleration. compares the performance of the GDI engine with a conventional MPI engine.

Improved volumetric efficiency

Compared with conventional engines, the Mitsubishi GDI engine provides better volumetric efficiency. The upright straight intake ports enable smoother air intake. The vaporization of fuel, which occurs in the cylinder at a late stage of the compression stroke, cools the air for better volumetric efficiency.

Motronic M3

The combination of ignition and injection control has several advantages. The information received from various sensors is used for computing both fuelling and ignition requirements. Perhaps more importantly, ignition and injection are closely linked.

information gathered during both prototyping and development of the engine. The main parameters for ignition advance are engine speed and load, but greater accuracy can be achieved by taking further parameters into account, such as engine temperature. This provides both optimum output and close control of anti-pollution levels. Performance and pollution level control means that the actual ignition point must, in many cases, be a trade-off between the two.

The injection system is multipoint and, as is the case for all fuel systems, the amount of fuel delivered is primarily determined by the amount of air drawn into the engine.

Last word

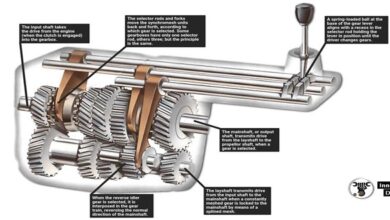

Electromagnetic injectors control the fuel supply into the engine. The injector open period is determined by the ECU. This will obtain very accurate control of the air-fuel mixture under all operating conditions of the engine. The data for this is stored in ROM in the same way as for the ignition. shows the components of this system.

Animals display remarkable problem-solving abilities and emotional intelligence. Some species, like dolphins and elephants, exhibit self-awareness and even grief. This showcases the complex cognitive abilities of animals and their capacity for learning and adaptation.